|

MEERSCHAUM

Meerschaum may have white, yellowish, gray or

reddish and mat colors. Its hardness degree is between 2-2.5, and it is

lightly adhesive and porous. It is extracted from 20-60-130 meters depth of

the ground as big and small rounds. Small rounds are collected by digging deep

wells and tunnels connected to these wells.

Some wells are watery, some wells are dry. Stones of watery wells are

much better. Meerschaum is produced in different places like

Pennsylvania, South Carolina, Utah, Mexico, Madrid, and Nairobi; however,

they are unimportant in quantity and low in quality. Meerschaum with the

highest quality is found in Eskişehir. The property that while drying it

keeps the remains of moisture and gases in its body, makes Meerschaum a

suitable material for making tobacco pipes as well as a good filling

material for absorbent, filter or isolation in industry. It became an

indispensable material in industry for years. It is used in making

cigarette-holder, tobacco pipe and decorative goods and in automobile

paint industry. It is added to porcelain paste, insecticides, powder and

stain removing medicines.

There three geological periods in its formation:

|

| First Order |

:

|

It is an ore in sandy- clay soil at

10-14 meters depth. |

| Second Order |

:

|

It forms between 40-60 meters depth. It is an ore

existing in clay. |

| Third Order |

:

|

Meerschaum with the highest quality forms in

Conglomera series and it exists in 80-130 |

| |

|

meters depth fitting with the topography. Other

kinds of meerschaum are: cotton-piece, granular cast, unit unity and

puny. |

|

|

The places where Meerschaum extracted from are: Sarısu, Yenişehir,

Türkmentokat, Gökçeoğlu, Karaçay, Söğütçük, Sepetçi, Margı, Nemli,

Kümbet, Yeniköy, Kepertepe, Karahöyük and Başören.

|

taken from

http://www.eskisehir-bld.gov.tr

Maintanance of the Meerschaum Pipe

Making the pipe

rest

Aiming to make the customers think that this hobby isnt that expensive the

sellers generally tell them that they should use only one pipe many times in

a day then make it rest for 1-2 days. But this appliance affects the smoking

quality badly. The most accurate way of smoking is to use 1 pipe only one

time in a day then make it rest for at least 1 day for merschaum pipes but

for briar pipes at least 2 days. This both makes the pipe relieved and increases

it quality , greatly. In order to apply this method correctly one can give

numbers to pipes and smoke these pipes according to order of the numbers.

|

Breaking in the

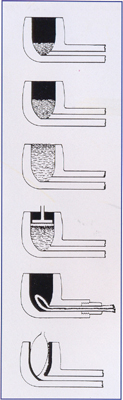

Pipes

Unlike the

briar pipes meerschaum pipes doesnt need any braking in process.

For briar pipes

the breaking in process is done as ;

The breaking in

process that is needed to prepare the briar pipes to the trees warmth and to the

tobacco , before smoking is firstly applied to pipes inner wall parts using the

carbon cake , which is formed in a few steps , i.e. firstly the pipes bowl is

filled up to 1/3 section, then the pipe is lighted and is smoked. After applying

this 1/3 filling process pipe smoked 2-3 times then filled 1/3 more and 2-3

times smoked again, after the remaining 1/3 section filled and smoked 2-3

times you can use your pipe as you want. The important part is to cool down the

pipe before filling it again , in order not to make the briar burned. When the

carbon cake is formed smoothly the pipe gets broken in.

This carbon

layer protects the Briar pipes from burning , so it is quite important for the

briar

pipes provided

that not exceed

2 mm

thickness.

Moreover the

carbon cake increases the Briar pipes smoking quality and pleasantness. This is

also effective at meerschaum pipes provided that it doesnt exceed the 2mm

level. If this cake exceeds 2mm then it may affect the quality in a bad way

giving a totally opposite result. Against all the others say some experienced

meerschaum pipe users dont clean out the carbon cake saying that making this

increases the quality at all.

Cleaning of The

Pipe

Cotton swab is

enough for cleaning the meerschaum pipe. Shaving foam , toothpaste , alcohol

etc. materials emphatically must not be used. Especially Savinelli Companys

See Spray is ideal for cleaning the briar pipes, but it is not suggested for

meerschaum pipes. That is to say , any spray should not be used for cleaning the

pipe , without considering its specialties.

|

After smoking

the pipe the remaining tobacco or tar that remains in bowl must be cleaned out.

While doing this process in meerschaum pipes one must be extremely careful ,

because the pipe spoon, pipe reamer, etc. tools may damage or scratch the pipe.

In order to

protect the pipe from blots we must keep our hands clean. Meerschaum pipes come

out after getting polished with beeswax. Especially, being sensitive to outer

effects while it is warm , is you touch the pipe with dirty hands then this dirt

will pass on the pipe, which would end up in unstable darkening. In addition to

this you must pay attention cleanliness of the pipe racks and pipe stands that

you put the pipe on, if you dont the dirt they possessed will remain trace on

the pipe.

Protection of

the Meerschaum Pipe

The tools that

are used in cleaning process of pipes must be used carefully and the pipe must

not be forced. Otherwise this may end up in cracks and corrosions.

Mouthpiece must

not be forced and must rotate counter-clockwise while removing and while putting

it in , it must be rotated clockwise. Otherwise the pipes connection parts

would be worn off and get slacked.

Never try to

remove the remainders out of the pipe by hitting it to a shoe heel , corner of a

table , an ashtray, etc. like you see on movies.

Pay attention

to pipe furniture that they must not be damaged which would scratch the pipe.

Fast smoking, too much smoking ,warming up too much makes the pipe darken with

no balance of inner and outer layers.

Smoking Quality

- Some briar

pipe users use whiskey, lemon , honey etc. to get a fine smoke but these types

of materials are not suggested to meerschaum pipe because these affects the

quality in a bad way, I suggest you aromatic tobacco instead

- Even though

the outlook of the pipe gets better , beeswax must not be used after the first

appliance or the smoking quality will get affected badly.

- As i

mentioned before carbon cake increases the smoking quality and pleasantness of

the meerschaum pipes like does at briar pipes, regardless of what some web sites

say, while it is not a needed material for meerschaums at all.

- Again as I

said before , you should make the meerschaum pipe rest for at least a day after

every smoking process which will increase the smoking pleasantness greatly.

|

Some

Accessories for Meerschaum Pipes

The

meerschaum pipe

accessories

are

the

same

as

other pipes accessories except

9mm meerschaum filters and meerschaum base stone filters.

I advise you to be used 9mm active carbon filter or 9mm balsa filter instead.

|

|

The Quality of

Meerschaum pipe

It is hard to

understand this from the outside .The most important method of understanding is

to test pipes lightness. Quality of the Meerschaum pipe is parallel to its

lightness (in weight).

The second

method is the change of colors while smoking ,but this would only occur in time.

The meerschaum of good quality changes its color stably.

The other tips

of the quality can only be understood by the experienced meerschaum pipe smokers

which is about the smoking quality.

Burak Demir

The

President of the Pipe Club of Turkey

http://www.turkiyepipokulubu.com

http://www.piposayfasi.com

Brief Historical Account of Meerschaum

At first

Meerschaum

was the two horse statues that bring in 20.000 old France silver liras to Puget

which was made at 1652 by the French Artist Louis Pierre Puget, who was a

student of Berini, in the garden of Vaux-Le-Vicomte Castle in France .At these

times we see 9 art masterpieces at the height of 17 cm. that were worked up

wonderfully of Puget which he considered them with all the details. These works

of arts are by order The Girl , The Eagle , The tree and its body , Victory

Monument , The Relaxing Bushed Brigant , are the first Meerschaum works.

Moreover the Meerschaum was worked up before 1652. Being not able to establish

the artists names and the regions they were , we are starting the history at

1652.

We see

the finished pipe, which was formed by the

first meerschaum , was made by a noble Hungarian Evangelist who made it from

two raw meerschaums that were given as a gift from the Sultan of the era. Giving

these two raw meerschaums to his friend Karol Kowates, who is a fancier of

pipes, Hungarian Evengalist Count Andrasay wants him to make something from

them. And Kowates makes the first meerschaum pipes that are displayed in

Budapest Museum now. The interest to meerschaum increases in Europe ,then the

first meerschaum factory gets build in Ruhla Town,

Germany. By 1745 there were 27

factories where over 150 craftsmen work in , in parallel with this the workers

number who work in meerschaum mines increases from 1600 to 6000 in Turkey.

|

Meerschaum pipe

was first shown to people by the craftsman Kristof Treiss in Leipzig Fair at

1750.

By 1777 in

Frankfurt Industry Fair two craftsmen Johanın Wolfgank Wagner and

Yakop

Helmann came from Ruhla showed their products which bring them plumes .- At

1812 meerschaum found its second importer firm named Benjamin Barling which is

an established firm in London.

England draws

attention of the world at 1851s for being a country which is able to use the

industrial explosions perfectly and utilizing the opportunities as well. Thanks

to meerschaum factories and their product the Crylal Plale Exhibition turns into

a world fair.

|

|

B.Bading is an

existing firm even now and like it a well-known firm GBD i.e. Ganneval Bondier

Donniger which was formed by three friends who have these names, starts

meerschaum production at 1851,in France. By 1852 a second Matthissa France Firm

was established which has 80 craftsmen working in. At 1850s the factory number

in Germany increases significantly and with no doubt we see that the German

Industry affects the Hungarian , Italian and Austrian Industries as well with

Hitlers regime. By this time we see there are at least 50 firms and 10-15

craftsmen in every of these firms just in Austria. It is impossible not to talk

about Vienna, because Vienna is the only place that gives spirit to meerschaum

and Vienna surely is the centre of places that gives woman beauty to meerschaum

and makes the mythology work up with meerschaum well.

By 1850

the number of craftsmen in Europe was 1500 and this quick widening of the

meerschaum industry between 1851 and 1854 makes us see Brothers M. and Emannel

Lzapek at

Czechoslovakia

, E.R at Belgium Brussels , Arthur Schneider at East Germany Leipzig ,

Snaland at Sweden and having the title of first woman pipe producer Helene

at Bulgaria Sofia set up one each firms. At that period which the meerschaums

exporting was hundred thousands covered money

there comes a new market on the scene. Calcuta at Middle-East, India and

D.Macropolo opens three factories at Bombay , Sri Lanka, Colombo .

In the very end

meerschaum was carried to America by the European artist F.J.Kaldenberg in raw

form in amounts of full two chests, which is nearly amount to 300 pipe all , at 1855.The first

American Pipe Factory was build on William Demuth Main Road and the first

meerschaum pipe store was opened in the name of William Demuth Company. Year

1862, the second store at Manhattan, year 1862 follows the firm of this

store,year 1896 the biggest meerschaum factory was opened at the south end of

101th Main Road Richmond Hill Queens, At Park Lane.

Speaking about

meerschaum and America, we shouldnt forget Vienna craftsman Gustav Fisher who

migrated to America by 1881.The fisher family made meerschaum managing

in a direct

line as 6 generations from 1742 to 1975, that is exactly 233 years. Born at

1887, Jr.Fisher was already a 74 year old pipe carver, who started this job at

14,when he died.

|